Superior craftsmanship, thoughtful customisation, and premium, eco-conscious materials are the foundation of every Cullen ring. The rest is shaped by you. We're here to collaborate — guiding you through each step to ensure your custom ring reflects everything you envisioned. But the journey doesn’t end at the final polish. We offer lifetime servicing, repairs, and ongoing aftercare, so your ring holds its meaning for decades to come. Here's what to expect when you choose Cullen to bring your made-to-order engagement ring to life.

The Production Process

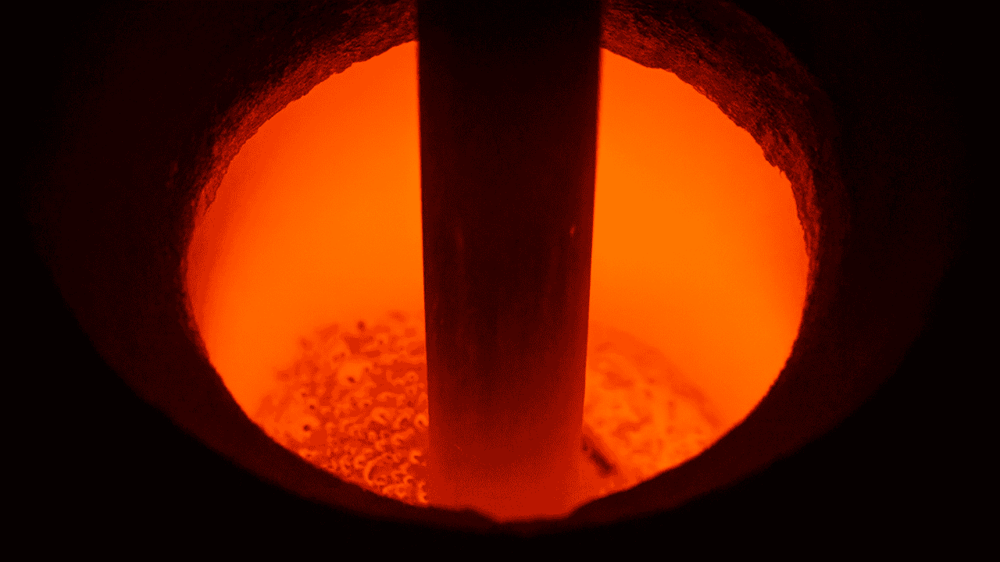

It starts with precision. Our Casting Specialists create your design using a 3D Computer Aided Design (CAD) before printing it in wax then encasing it in a plaster-like material to form a perfect mould. Once set, your chosen precious metal is poured in, cooled, and cast into the shape of your ring.

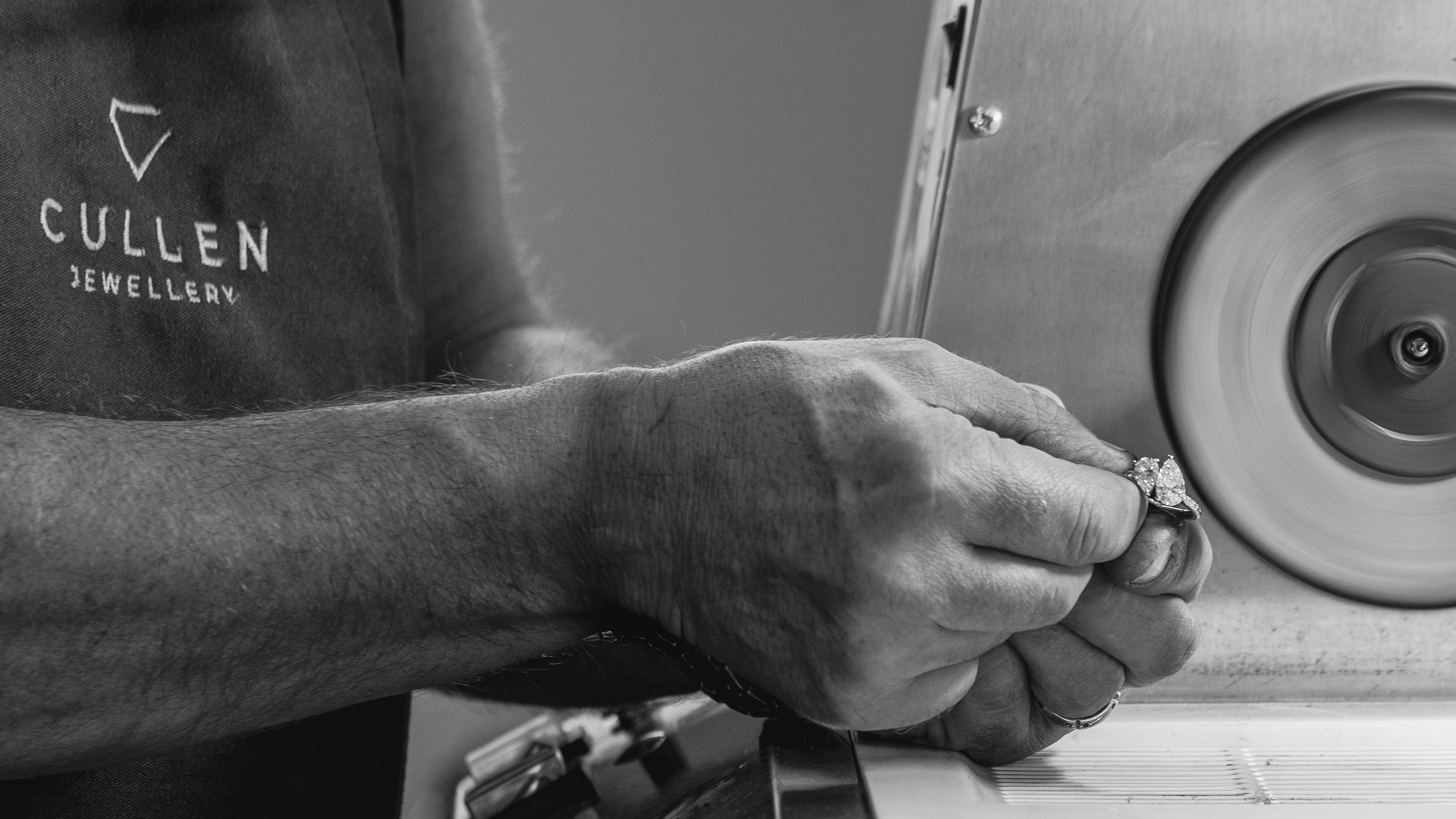

Then We Polish, and Refine

This is where your ring gets its mirror-like shine. Using a polishing wheel and buffing compound, our expert Polishers smooth every surface of your ring — even the places you can’t see — to a brilliant, uniform finish. Each ring is carefully balanced to achieve a high-shine look without compromising the strength of the metal, especially around claws and prongs once they’re securely shaped into place.

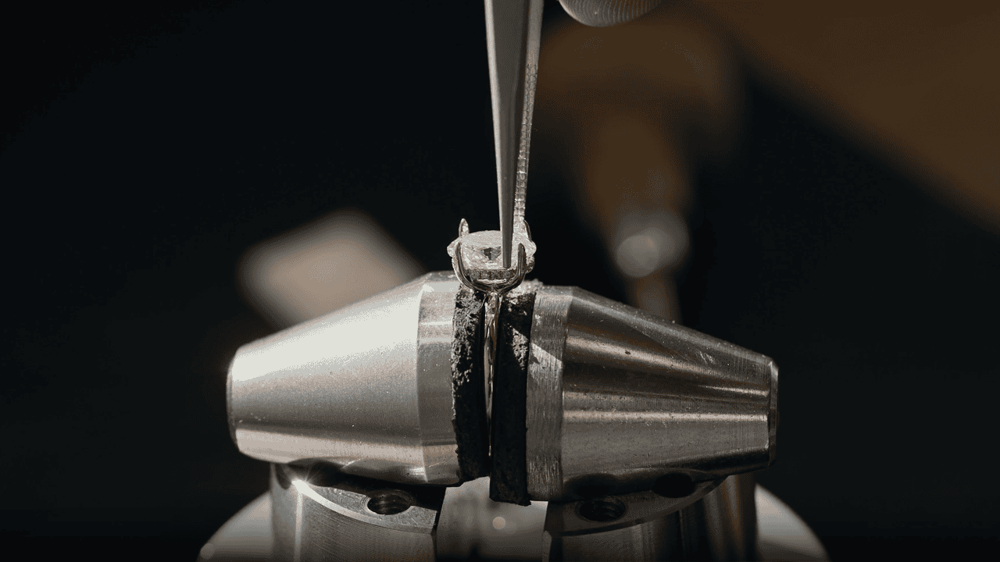

Time to Set the Stone

Here’s where your carefully chosen stones are secured into your ring. For designs with side stones or a hidden halo, a tiny space called a ‘seat’ is created for each stone to rest in. Then the basket is created: a framework of stems that connects the claws, lets light in from every angle, and reinforces the setting with lasting strength.

Next, our Gem Setters place each stone in its seat, using specialised tools to shape the surrounding metal into claws, which then are pressed gently over the stone. To ensure strength and beauty, claw thickness is finely adjusted to fit your gemstone’s size and dimensions offering security and maximised brilliance. The centre stone is set last — an essential step, as it bears the brunt of daily wear.

The Final Touches

Before you receive your ring, our Quality Control Specialists conduct a thorough review, including inspection under a 50x magnification microscope, to ensure it meets both your standards and ours. We then give it a final clean and polish so the metal and stones are clean, bright and brilliant. Now all that’s left to do is treasure it for a lifetime.